Michigan's Trusted Industrial Powder Coating Specialist

- ISO-9001:2015 Certified Powder Coating/Sandblasting Company

- AS-9100 Certified Anodizing Company

- State-of-The-Art facility for Enterprise Solutions

- Expedited Delivery + Rapid Turnaround

- Large Weight Capacity - Up to 10,000 Lbs.

- Emergency Service Available

MICHIGAN POWDER COATING

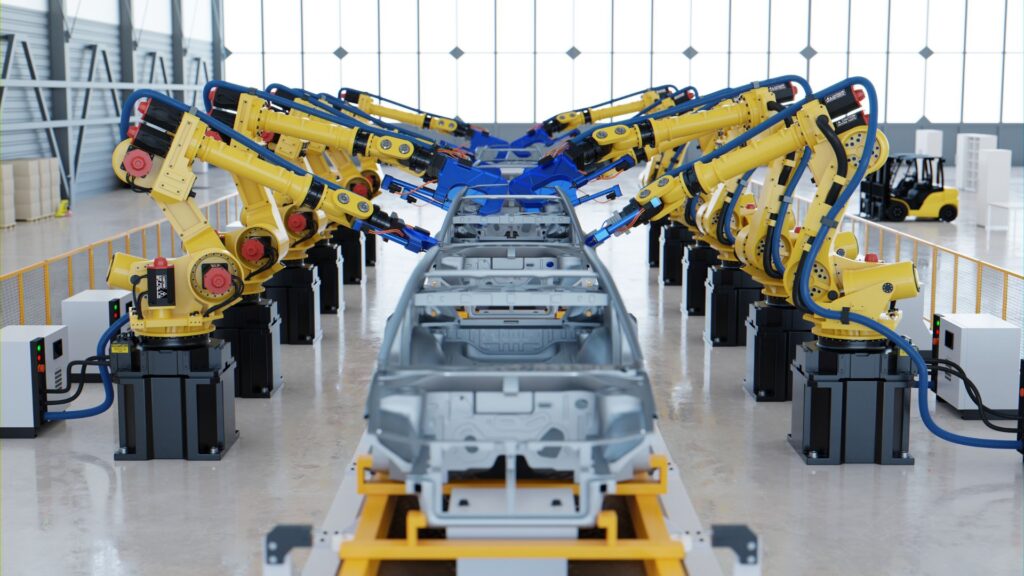

At Liberty Powder Coating, we provide expert powder coating services designed to enhance the durability and appearance of metal products. Powder coating is an advanced finishing process that involves applying a dry powder to metal surfaces. This powder is then heated to form a smooth, hard coating that resists scratches, chipping, and corrosion. Our services cater to a wide range of industries, including automotive, manufacturing, architecture, and more, offering long-lasting protection and a flawless finish for any metal part.

Our powder coating services include a variety of finishes, such as gloss, matte, metallic, and textured options. With an extensive color selection, we can match your specific design needs while providing a finish that is both functional and aesthetically appealing. We utilize state-of-the-art equipment to handle projects of all sizes, from single custom jobs to large-scale industrial production.

OUR CAPABILITIES

General Powder Coating Capabilities

- MIL-PRF-24712B for typical powder coating components and assemblies

- MIL-PRF-32348 for CARC (we process the following)

- Type I, Class I for Powder Primer

- Type II, Class I Powder Primer / Interior Topcoat

- Type III, Class I Powder CARC Topcoat

- Abrasive cleaning perA-A59316 type-I, grade-D

- Epoxy powder electrostatic coating, color FED #31350 red per SAE AMS FED STD 595

- MIL-STD-130 (Identification & Traceability)

- ASTM-D3951 (Packaging & Packing)

Military/Aerospace

- We process media blasting, primer, and powder coating for several military service projects

- MIL-PRF-24712A

- MIL Black 383 (FS595-37030)

- SAE AMS 3143 per AMS-STD-595

Medical

- MIL-PRF-24712B for typical powder coating components and assemblies

- MIL-PRF-32348 for CARC (we process the following)

- Type I, Class I for Powder Primer

- Type II, Class I Powder Primer / Interior Topcoat

- Type III, Class I Powder CARC Topcoat

FDA (Food/Drugs)

- We are a fully FDA-compliant powder coating company that works with materials suitable for medical, food-grade, and food contact applications

ACE (Agricultural)

- We are an ACE certified company who operates in full compliance with all agricultural laws involving crops, livestock, etc.

di-electric

- Powder coating processed used as a electric insulator for motor housings

- Customer Masking

- Passed 5KV testing (controlled powder thickness of min 350µm / 550µm)

Robotics

- Robotic & safety workplace systems

- Conveyor technology

- Protection Systems

- Powder coating of customer colors provided

- Anodizing supplied

OUR PROCESS

01

Pretreatment

02

Powder Coating

03

Packaging

ISO Certified Company

We are proud to be an ISO-9001:2015 certified company, which demonstrates our commitment to maintaining the highest standards in quality management systems.

Why Choose Us

michigan's top rated metal coating company

Unmatched Expertise in Coatings

Decades of experience in the industry ensure superior quality & craftsmanship in every project.

Advanced Equipment and Technology

Commitment to Quality and Compliance

Customized Solutions for Every Client

Advanced Coating Capabilities for Industrial Success

Where Powder Meets Precision

Explore our extensive capabilities in handling diverse and large-scale powder coating projects.

Capabilities:

- Weightlifting capacity of 10,000 pounds

- Three wash and phosphate stations

- Three new spray booths with cartage filters, complete with LED lighting (Deere & CAT requirements')

- Gema, Nordson, Wagner application equipment (powder spray guns)

- Multiple oven sizes up to 22' in length and 10' in width, (Batch System)

- Inspection: Mil Thickness gaging, X-Rite Color Solutions, MEK cure testing, Crosshatch adhesion testing

- Custom protective wrapping provided (or customer dunnage utilized)

- LPC logistics available (Up to 28' Capacity)

- Specializing in prototype and ultra-low volume production with high quality

- Expedited processing offered: multiple shifts, weekend processing

- Two scheduled production shifts, up to 7 days a week

- Sand Blasting - Pretreatment

- Masking and Plugging - Pretreatment

- Burn Off - Pretreatment

- Chemical Stripping

Answers at Your Fingertips

Frequently Asked Questions

What is powder coating?

Powder coating is a dry finishing process where a powder is applied to metal surfaces and cured under heat to form a durable, protective coating. It provides a tough, attractive finish that resists chipping, scratching, and fading.

What types of materials can be powder coated?

Powder coating is primarily used on metal surfaces, including steel, aluminum, and iron. It’s commonly applied to automotive parts, industrial equipment, outdoor furniture, and architectural components.

How long does powder coating last?

With proper care, powder coating can last for 15-20 years. It offers excellent resistance to environmental factors like UV rays, moisture, and chemicals, ensuring long-term durability.

Is powder coating environmentally friendly?

Yes, powder coating is eco-friendly. It contains no solvents or harmful VOCs (volatile organic compounds), making it a safer option for both the environment and workers.

Can I choose custom colors and finishes?

Absolutely! We offer a wide range of colors and finishes, including matte, gloss, metallic, and textured options. Custom color matching is also available.

Can powder coating be applied over rusted metal?

No, all surfaces must be clean and free of rust, grease, or other contaminants. We offer sandblasting and pretreatment services to ensure the metal is properly prepared before powder coating.

What is the difference between powder coating and traditional paint?

Powder coating is more durable and resistant to chipping, scratching, and corrosion compared to traditional paint. It’s also more environmentally friendly since it doesn’t require solvents.

How long does the powder coating process take?

The turnaround time depends on the size and complexity of the project, but most jobs can be completed within a few days. We’ll give you an estimated time frame when you place your order.

Can you handle large or custom projects?

Yes, we are equipped to handle projects of all sizes, from small custom parts to large industrial production runs. Let us know your needs, and we’ll work to accommodate them.

check out some of our industry partners

Trusted by Industry Leaders

Liberty Powder Coating is proud to collaborate with premier suppliers and renowned industry giants. Our partnerships with companies like Axalta, AkzoNobel, PPG Industries, and Sherwin-Williams reflect our commitment to top-tier quality and innovation.

contact our team of experts

Connect With Us

Looking to enhance your industrial components with top-quality coatings? Reach out to Liberty Powder Coating – Michigan’s trusted partner in advanced powder coating and sandblasting solutions. Our dedicated team is on hand to discuss your project’s unique requirements and provide expert guidance every step of the way.

Let's Discuss Your Next Project!

Use our online contact form below with your project details, and we’ll provide you with a customized solution tailored to your specifications. Our experts aim to respond to all online inquiries within one business day.

"*" indicates required fields